Warehouse Gravity Self Slide Rack

Product feeds to Picking Position by Gravity Flow

Carton flow rack system for every size warehouse and every price range are gravity driven and perfect for applications with numerous SKUs. Inventory rotation is ensured with First-in/first-out psentation basis. Separating the loading aisle from the retrie

val aisle allows pickers to operation more efficiency. Carton flow rack user sloped shelves to improve visibility and order accuracy and is perfect answer for split case or piece picking.

Carton flow rack can be integrated with co

nveyors and other warehouse storage solutions to create functio

nal pick modules and picking efficiency.

Technical Des

criptions self slide rack

| Style |

Carton flow rack system, gravity sliding runner

|

| Selection |

Single row, multiple rows

|

| Dimension of rack | 1, popular sizes W2000*D600*H2000/W2000*D400*H2000

|

Components

(medium duty

200KG~800KG) | 1, step beam: 60*35/80*35mm

2, uprights: 55*45/60*45mm/80*60MM

3, Thickness: step beam: 1.2~1.5mm; upright:1.2mm~1.5mm

|

Components

(heavy duty

100KG~500KG) | 1,Beam: 80*45mm/90*45mm

2, uprights: 80*60mm

3, Thickness: Beam: 1.5~1.8mm; upright:1.5mm~1.8mm |

| Colour | RAL2004+RAL5015

( www.ralcolour.com) |

| Weight capacity | 100KG~500KG per level |

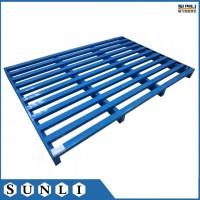

| Package | 1, Less than one container: steel pallets/steel straps/plastic film

2,full container: plastic film/steel pallets for items |

| Services | CAD drawings for rack layout; CAD drawings for installation |

Detailed image for self slide rack system

Overall view for self slide gravity rack system

Application for carton flow rack system/self slide

Please inform us following information to get prompt offer for self slide rack

Please inform us following information to get prompt offer for self slide rack+ The dimensions of single rack unit ( or palletized load des

criptions)

+ The palletized payload

+ Row of racks( single row, back-to-back row or multiple rows)

+ How many palletized load within one unit

( Please refer to the

Product Description on the top)

FAQ1, What is MOQ limitation for self slide rack?

++ NO. But large purchase will bring competitive prices, 20FT co

ntainer ( 10T~13T) is highly recommended, so that production can be better handled.

2, What is the lead time in Sunli?

++ As per 20FT co

ntainer loading, manufacture time is a

bout 21days; Regarding some customized items 25~27days will be covered.

3, What is payments methods Sunli can accept?

++ T/T and L/C are welcomed.

4, How a

bout Sunli's sample delivery?

++ Short section of uprights and beams can be provided free of charge. But the freight will be collected upon your duty.

5, What is warranty for Sunli's rack system?

++ All rack items will be warrantied against manufacture's defects.

++ To avoid any shortage or missing components, we will provide 1%~2% spare parts besides basic ones.