Material | 1.Sand casting&Gravity casting&Low pssure die casting: A356/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/ENAC-42100/ENAC-42200/EN AC-43000/ENAC-43200/EN AC-46000/EN AC-46200 2.High pssure die casting: A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ENAC-46000/ENAC-46100/ENAC-46200/ 3. CNC machining casting: 6061-T6/6063-T6 |

| Processing | Sand casting, Gravity casting, high pssure die casting, low pssure die casting and CNC Machining casting. |

| Design | As per the customer's drawings |

| Equipment of Casting | 1.High pssure die casting machining: 125T/180T/250T/ 280T/500T/800T/1250T 2.Gravity casting machine: 5 production lines 3.Low pssure die casting machining: 1 production line 4.Sand casting machine: 6 production lines 5.Degassing equipment and opportunities to refine the material 6.Machining: 3Sets CNC Machine;3 sets Milling machine; 3 sets Turning machining; 10 sets drill and tap machine |

| Testing Facility | Spectrometer, tensile test machine, hardness test machine, CMM dimension report |

| Certificate | ISO9001:2008/SGS |

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards |

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF |

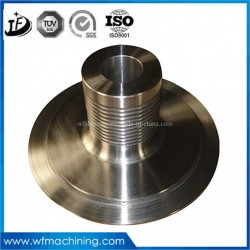

| Precision Machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Service | OEM service available,produce according to customer's drawings |

| Products & Application Scope | All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on |

| Advantages | 1. Lutz works with over 8 years in Aluminum casting for Japanese and German market; 2. Lutz have four casting types producing lines; 3. Near Sea Port and Air Port; 4. Passed ISO9001:2008/SGS ; 5. OEM service according to customers'drawings; 6. From Casting to finished surface, owned casting, polishing and plating workshops.Wcan offer good quality and strict delivery time; 7. With samples and order: We can offer dimension report,Chemical composition and Mechanical properties; 8. Control material with spectral and thermal analysis equipment (density and processing); 9. Spectral analysis of raw-material and liquid melt, batch before casting. |

Chinasuppliersonline is not responsible for the accuracy, authenticity, or legality of any information posted by suppliers. Chinasuppliersonline will not be involved in legal disputes arising from transactions between customers and suppliers. Chinasuppliersonline is a platform which connects potential buyers to potential sellers.

If your legal rights are violated, you are welcomed to send an email to our in-box. For issues arising from infringements, complaints, please contact wwwctmorg@gmail.com

|

|

|

|

|

|

|

|