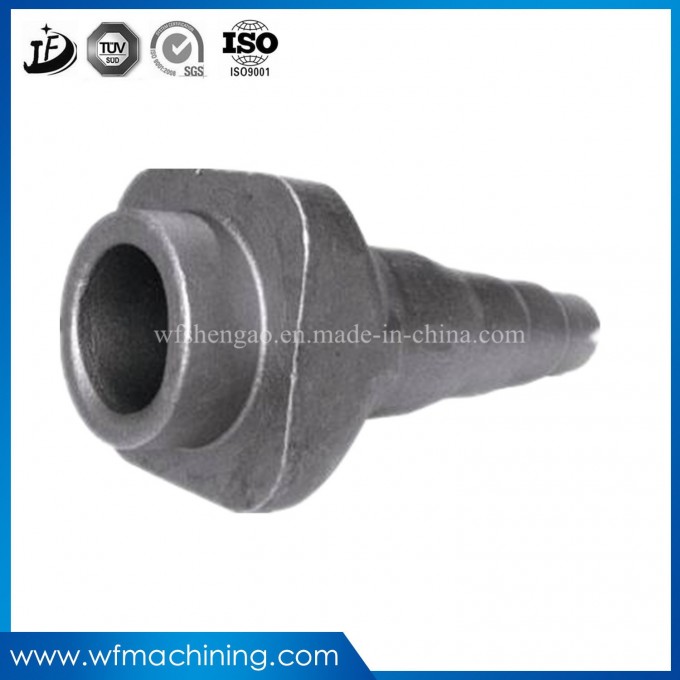

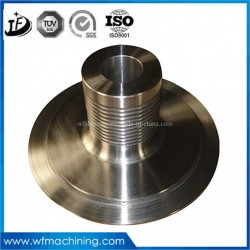

| Features:Forging |

1)Materials:Grayiron,ductileiron,malleableiron,carbonsteel,Alloysteel,stainlesssteel,aluminum,bronze,brass,etc.

|

| 2)Standard:JIS,DIN,ASTM,BS |

3)Surfacetreatment:ElectroZincPlatingHotdeepzincplating,Electrophoresis,Powder

coating,Painting,Shootblastingetc.

|

| 4)Weight:0.1-10,000kg |

5)Processes:Forging,SandCasting,InvestmentCasting,PrecisionCasting,CNCMachining.

|

6)Manufacturingequipments:threedie-forgingproductlines(3tonstampforginghammerproductline,

1000tonfrictionproductline,1250tonpssproductline),variousloosehammersandcylinderparts,

automaticcontrolringforgingmachine,heattreatmentcellar,digitalcontrolfibrenaturalgascarfurnace,

standingmachinetool,machinetools,standingmiller,standingdrillmachine,benchdrillmachine,

CNCmachiningcentreetc |

| 7)Testingequipment:Supersonicinspectionmachine,Supersonicflawdetectingmachine,physicsandchemicalanalysis. |

| 8)Services |

| a)Alsocandesignandmanufactureforgedaccordingtothecustomers'requirement |

| b)ISO9001qualitycontrolandinspection |

| c)Inhouse&ThirdParties |

| d)Orderingandwarehousing |

| 9)Packing:Woodencasesoraccordingtocustomers'needs |